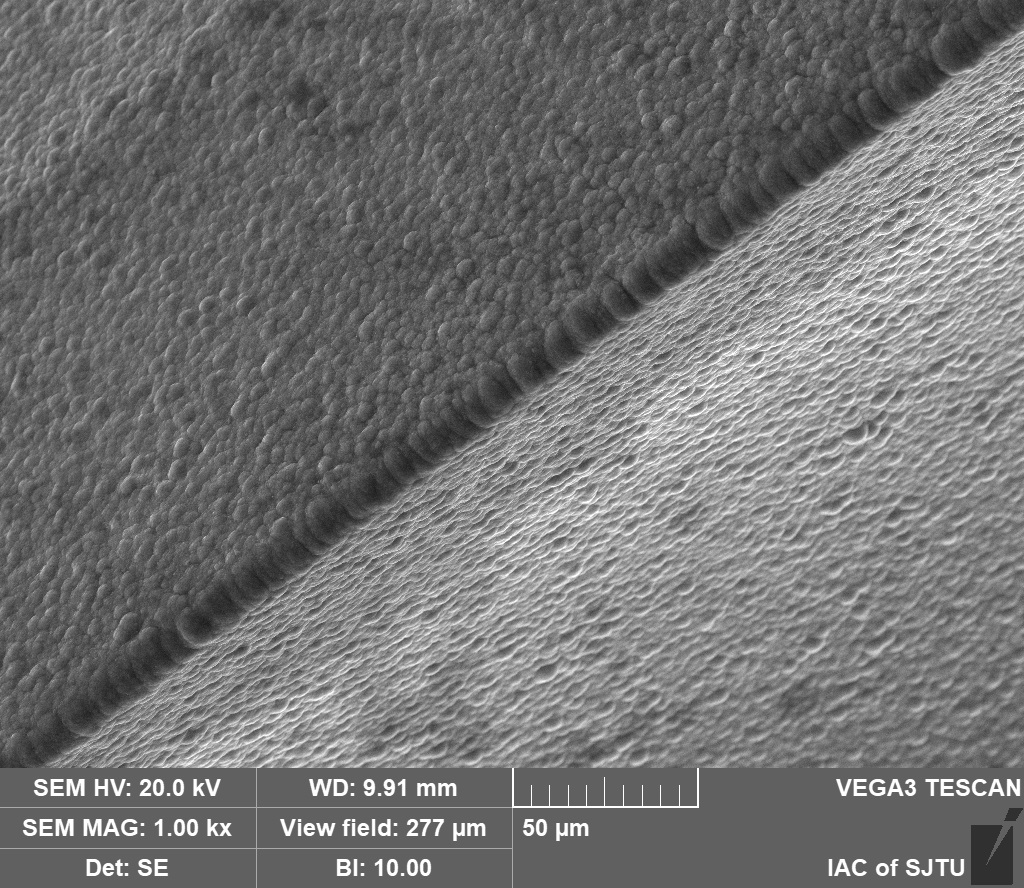

CVD Diamond Coated Dental CAD CAM Milling Tools for Zirconia

CVD diamond coated milling burs are the most advanced type of zirconia milling burs. They are made with a process called CVD (chemical vapor deposition), which bonds a thin layer of diamond particles to the cutting edge. This creates a very strong and durable coating that can withstand the high temperatures and pressures generated during milling. CVD diamond coated burs offer the longest lifespan of all types of zirconia milling burs, but they are also the most expensive.

More ...

Dental CAD CAM Milling Tools for PMMA PEEK Trilor

New composite coating treatment for milling PMMA/PEEK Trilor materials. Can provides lubricity and superior wear and corrosion resistance. Our PMMA/PEEK Trilor tools have a very low residual stress, which provides for the best adhesion and ductility. High hardness, low coefficient of friction and the low residual stress.

More ...

Dental CAD CAM Milling Tools for Glass Ceramic

For machining Lithium glass and other glass ceramic, our grinding burs with an advanced abrasive diamond grit in different grain sizes applied by a unique electroplating process. Our diamond plated grinding tools provide the long time tool life while producing accurate grinding results.

More ...

Dental CAD CAM Milling Tools for Metal Titanium Cobalt Chrome

Our hybrid coating dental CAD CAM milling burs for milling Titanium, Cobalt Chrome and other metal dental materials.

More ...

CVD Diamond Coated Carbide Inserts

A carbide insert is a tool used for accurately machining metal. Steel, carbon steel, cast iron, alloys at high temperatures, and non-ferrous metals with easy surface finishes can all be cut using this machine. You can easily replace the grips since many different types, sizes, shapes, and colors are available.

More ...

CVD Diamond Coated End Mills

High performance diamond coated carbide tools for your non-ferrous material applications. Possibly the best diamond adhesion in the coated tool industry

More ...

CVD Diamond Coated Drill

CVD Diamond Coated Drill created specifically for high tool life and increased resilience the tools allow manufacturers to optimize operations and reduce tooling time and cost.

More ...